Material: PP

Features: It is easy to carry when traveling, and also great for home use.

Usage: It’s perfect storage containers for mascara cream, liquid eyeliner, eyelash growth liquid and so on.

Design: easy to carry, the bottom is easy to fill; Quality Assurance, quality worry-free, support customization

Jiangyin beauty packaging is the OEM customized colourful plastic perfume bottle manufacturer, pocketsize plastic perfume bottle, welcome to consult low MOQ plastic perfume bottle latest price.

Professional packaging.

Light feel,

moderate spray amount,

small and practical,

high-cost performance

Environmental tasteless.

Simple fashion

Light and portable

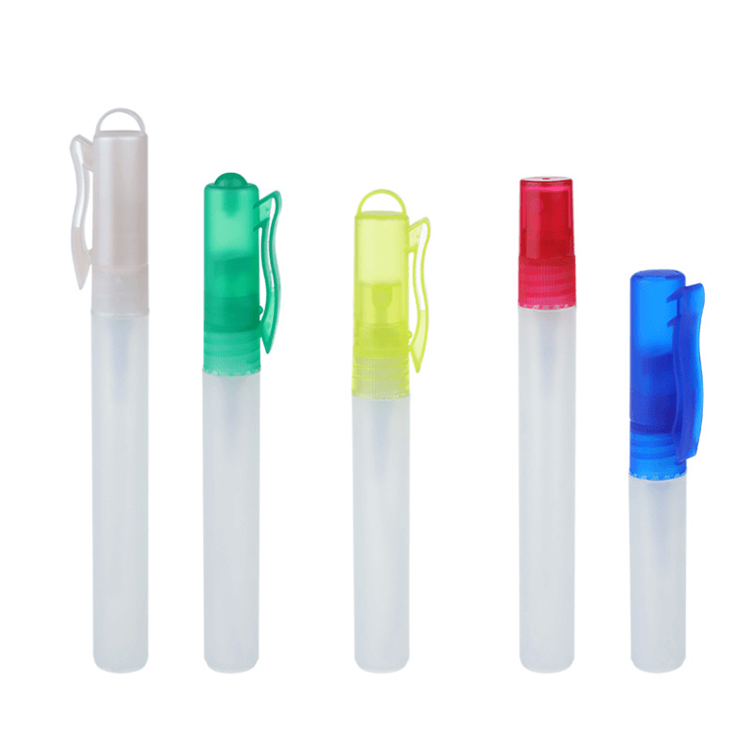

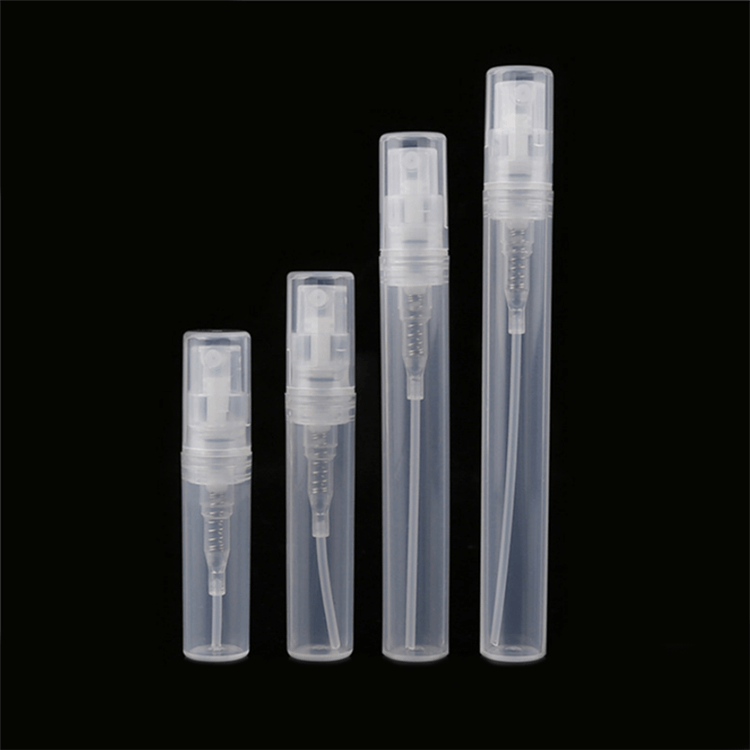

Shape: Portable card perfume bottle、Round Flat shoulder、Round Oblique shoulder、Perfume pen、Shaped

Capacity:2ml,3ml,4ml,5ml,10ml,20ml,30ml,50ml,60ml,80ml,100ml

Colour: Customizable colors

Price FOB shanghai:$0.04-0.12/pc

MOQ:500-10000

Plastic mascara bottle

Make-up packaging.

24-hour Online consultation.

Damage compensation

Since entering the Chinese market, plastic bottles have been light in weight, easy to carry, not afraid of falling, and resistant. Jiangyin beauty packaging is the OEM customized colourful plastic perfume bottle manufacturer, pocketsize plastic perfume bottle, welcome to consult low MOQ plastic perfume bottle latest price.

Acid and alkali resistance and other characteristics are widely loved by dealers and consumers, so in just a few decades quickly take root in the packaging industry. Up to now, plastic bottles have become an important part of life.

Beverages, food, pickles, and honey have been covered by the plastic bottle industry, even farmers, animals and doctors.

The packaging is also gradually monopolized by plastic bottles. But do you know how plastic bottles are made?

Plastic bottles are part of the rubber and plastic industry. No matter what plastic bottles they are, they must be molded.

Processing. The molding process of plastic bottles is a phenolic resin, urea-formaldehyde resin, and unsaturated polyester tree.

The process of making plastic products from polymers such as grease. The processing method comprises compression molding, extrusion molding, injection molding,

Blow molding, calendering, etc. Next, we will introduce your processing method in detail.

Compression molding is also called compression molding in industry, which is used for phenolic resin, urea-formaldehyde resin. Forming thermosetting plastics such as Unsaturated Polyester Resin is the first step in plastic bottle processing technology. Jiangyin beauty packaging is the professional plastic perfume bottle manufacturer, colourful plastic perfume bottle pricelist, welcome to consult.

Extrusion, also known as extrusion molding, uses an extruder to continuously pass the heated resin through the mold a method of extruding a product of the desired shape. Its advantage is that it can extrude products of various shapes, high production efficiency, automatic and continuous production; the disadvantage is that thermosetting plastics cannot be widely collected. With this method, the product size is prone to deviation.

Injection molding can also be called injection molding. Injection molding is the use of injection molding machines to convert thermoplastics. Jiangyin beauty packaging is the OEM customized colourful plastic perfume bottle manufacturer, pocketsize plastic perfume bottle, welcome to consult low MOQ plastic perfume bottle latest price.

A method in which a melt is injected into a mold under high pressure and cooled and solidified to obtain a product. Excellent injection molding. The point is that the production speed is fast, the efficiency is high, the operation can be automated, and the parts with complex shapes can be formed. It is especially suitable for mass production. Disadvantages are the high cost of equipment and molds and difficult cleaning of injection molding machines.

Blow molding is also called hollow blow molding. Mainly by means of the pressure of compressed air to close in. A method of blowing a hot resin blank into a hollow product in a mold, wherein blow molding comprises blow molding thin two methods of film and blow molding hollow products. Blow molding is mainly used to produce film products, various bottles, barrels, pots, etc.

Calendering Calendering is to pass the resin and various additives through the calendar after being expected to be treated. The gaps of one or more calendar rolls with opposite steering are processed into films or sheets, which are then processed from the calender A forming method in which a roller is peeled off and cooled and shaped. Calendering is a PVC tree the main molding method of grease is to manufacture films, sheets, plates, artificial leather, floor tiles, etc.

The main means of the product.

Foaming molding add appropriate foaming agent into the foaming material to make the plastic produce microporous knot the process of construction. According to the cell structure, it is divided into open-cell foam and closed-cell foam, which are made. Jiangyin beauty packaging is the professional plastic perfume bottle manufacturer, colourful plastic perfume bottle pricelist, welcome to consult.

The method of making is determined.