The material of the aluminum screw cap is aluminum. It is environmentally friendly and odorless.

It can avoid leaking of water, oil, cream, gel or lotion inside the container.

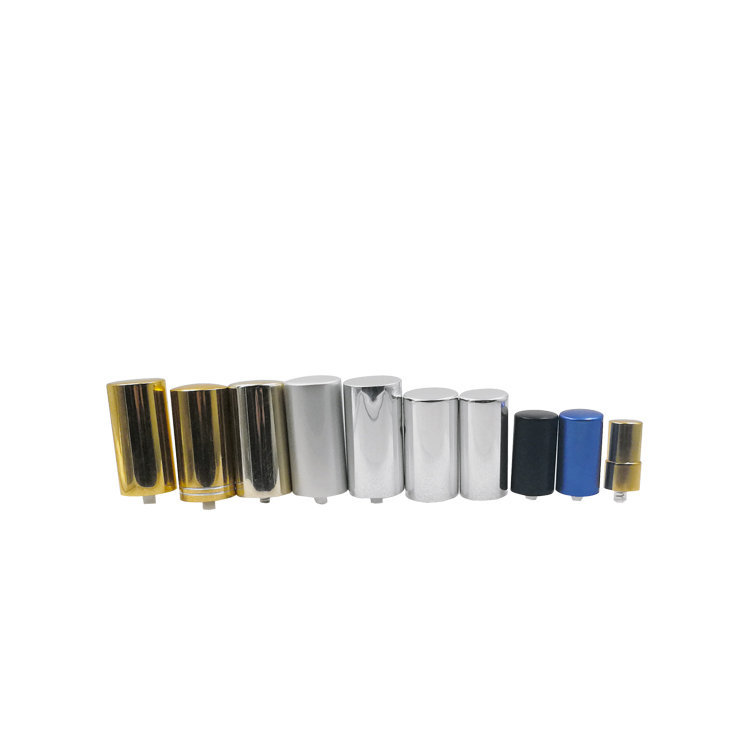

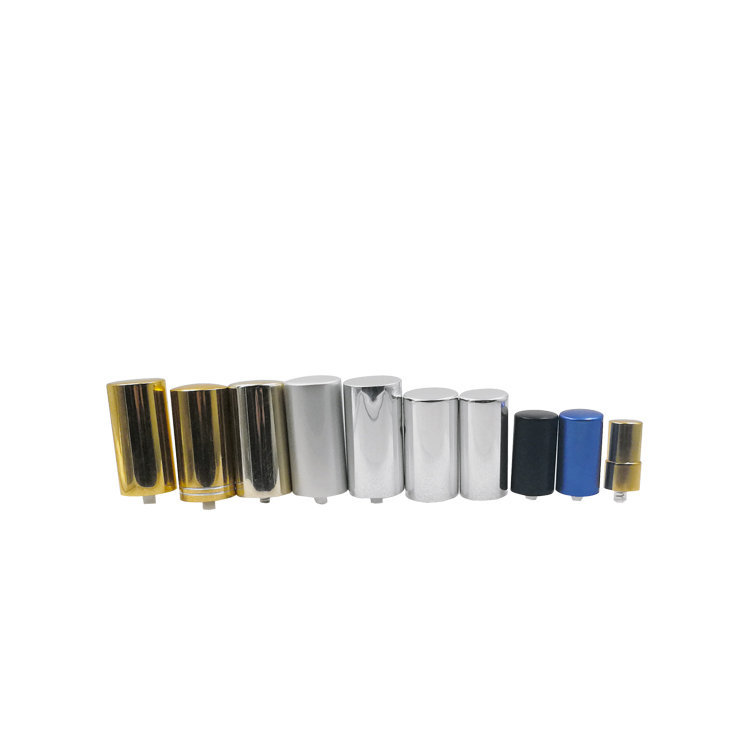

The design is very simple and generous. The color can be customized and the design is very light and handy. You can print or emboss the logo on the top. Jiangyin beauty packaging is the professional aluminum cap manufacturer, sells low MOQ aluminum cap, welcome to consult free sample aluminum cap optimal price.

Professional packaging.

Small and convenient.

Easy boarding.

Easy and comfortable.

Recyclable.

Environmental tasteless.

Material: aluminum

Shape: different shapes and colors can be made as per your requirements or samples

Size:15/18/20mm

USE for: plastic inner sleeves

MOQ:10000PCS

Price: FOB shanghai $0.03-0.1/pc

Use:cream,lotion

Make-up packaging.

24-hour Online consultation.

Damage compensation

Jiangyin beauty packaging is the professional crimp on colourful aluminum cap manufacturer, buy OEM customise aluminum cap at factory price.

Silkscreen printing, custom sticker, hot stamping, matte, frost, offset printing, embossing

Aluminum overlap is mostly processed in highly automated production lines, so they have strict requirements on the strength, elongation and size deviation of materials, or they will break or crease during processing. In order to ensure the convenience of printing after the bottle cap is formed, it is required that the bottle cap material plate has a flat surface and no rolling marks, scratches, and stains. Generally, the alloy used is 8011-h14, 3003-h16, etc. The material specifications are 0.20mm ~ 0.23mm in thickness and 449mm ~ 796mm in width. The production of aluminum bottle cap material can be made by hot rolling or continuous casting and rolling, which are rolled by cold rolling. At present, the anti-theft cover material manufacturers in China use more continuous casting and rolling billets than rolling billets. Jiangyin beauty packaging is the professional aluminum cap manufacturer, sells low MOQ aluminum cap, welcome to consult free sample aluminum cap optimal price.

Dongfang news on September 17: according to insiders, China’s anti-theft bottle caps will grow by 10% per year. In 2010, about 15 billion anti-theft bottle caps will be needed, and 53,500 ~ 60,000 tons of aluminum plates and ribbons will be needed. The demand for aluminum caps is growing fast. At present, most of the packages of liquor, wine, medicinal wine and beverage in China are still made of broken glass bottles, and many of the caps are made of aluminum. At present, China’s various liquor manufacturers have tens of thousands. Jiangyin beauty packaging is the professional crimp on colourful aluminum cap manufacturer, buy OEM customise aluminum cap at factory price.

According to data, in recent years, the annual production of liquor is about 8 million tons, of which about 50% of the bottles use the anti-theft lid.

Alcohol security is more and more attention by manufacturers, bottle cap as a part of the package, its anti-counterfeiting function and production form has been toward the diversification, high-end development, twist, open, can sing, can talk, multiple anti-counterfeiting bottle cap is widely used by manufacturers. Despite the changing features of the anti-counterfeiting caps, there are two main types of materials, namely aluminum, and plastic. Internationally, most wine bottle caps are made of aluminum, which is characterized by simple appearance, fine production, uniform color and exquisite design with advanced printing technology. Compared with plastic bottle caps, aluminum overlaps not only have good performance but also have low cost, no pollution and can be recycled.

Plastic anti-counterfeiting cover has a complex structure and anti-reverse irrigation function, and its surface treatment technology is diverse, strong three-dimensional sense, unique and novel appearance, but its inherent defects cannot be ignored. Due to the use of thermoforming technology of glass bottles, the size error of bottle mouth is large, and it is difficult to achieve high sealing. Packaging experts pointed out that due to the presence of strong static electricity, the plastic bottle cap is easy to absorb dust in the air, coupled with ultrasonic welding generated by the debris is difficult to eliminate, the problem of plastic debris to alcohol pollution has not been completely solved. In addition, in order to reduce costs, some manufacturers of plastic bottle caps have adulterated their raw materials. The sanitary condition is worrying. Because the bottle caps are partly connected with the glass bottle mouth, it is not easy to recycle. In addition, compared with aluminum bottle caps, plastic bottle caps cost about – times or more. Jiangyin beauty packaging is the professional aluminum cap manufacturer, sells low MOQ aluminum cap, welcome to consult free sample aluminum cap optimal price.

In contrast, aluminum anti-theft bottle caps can overcome the above shortcomings of plastic bottle caps. Of course, aluminum bottle cap also has some defects, such as different side colors of the bottle cap, easy to produce paint off phenomenon, the appearance of lack of change, but these problems can be found from the technical solution. The aluminum anti-theft bottle cap is made of high-quality special aluminum alloy material, which is mainly used for packaging of wine, beverage (including gas and excluding gas) and medical and health care products, and can meet the special requirements of high-temperature cooking and sterilization.

There are nearly 200 aluminum overcap manufacturers in China, with an annual design and production capacity of about 9 billion, among which nearly 30 production lines have been introduced and the output is more than 5 billion, which can produce nearly 100 kinds of bottle caps. aluminum overlap is mostly processed on highly automated production lines, so the requirements for strength, elongation and dimensional deviation of materials are very strict, or they will break or crease during processing. In order to ensure the convenience of printing after the bottle cap is formed, it is required that the bottle cap material plate surface is flat and free of rolling marks, scratches and stains. The production of aluminum bottle cap material can be made by hot rolling or continuous casting and rolling, which are rolled by cold rolling.

However, according to the report of the manufacturer of anti-theft cover, the effect of using anti-theft cover is better than that of casting and rolling blank.

Our country packs the liquor, the wine, the medicine liquor, and the beverage and so on the majority still gives priority to by the glass bottle, among them about 50% wine bottle cap is USES the aluminum material manufacture theftproof cap. China’s anti-theft cap will grow by 10% per year. It is estimated that by 2010, the amount of anti-theft cap will reach 15 billion, with about 60,000 tons of aluminum plate and strip.

It is known that there are nearly 200 aluminum overcap manufacturers in China, with an annual design capacity of about 9 billion, including 30 introduced production lines with a capacity of more than 5 billion, which can produce nearly 100 kinds of bottle caps. aluminum overlap is mostly processed on highly automated production lines, so the strength, elongation and dimensional deviation of the material are strictly required, or they will break or crease during deep drawing. Jiangyin beauty packaging is the professional crimp on colourful aluminum cap manufacturer, buy OEM customise aluminum cap at factory price.

In order to ensure the convenience of printing after the bottle cap is formed, it is required that the bottle cap material board has a flat surface without rolling marks, scratches and stains. Generally, alloy materials such as 8001 — HI4 and 3003 — H16 are adopted. The normal thickness of the material is 0.20 — 43.23mm, the tolerance is ±0.1%, and the width is 449-796mm. The production of aluminum cap material can be made by hot rolling or continuous casting and rolling, which are rolled by cold rolling. Production practice shows that hot-rolled billet is better than cast rolled billet in the application effect of anti-theft cover. Jiangyin beauty packaging is the professional aluminum cap manufacturer, sells low MOQ aluminum cap, welcome to consult free sample aluminum cap optimal price.